The working principle of thermal power plants or nuclear power plants is still essentially boiling water. This water requires a relatively high level of cleanliness:

| indicator name | Requirement value (Runing) | detection method | core meaning |

|---|---|---|---|

| Conductivity (25 ℃) | ≤0.1 μS/cm | Conductivity meter method (GB/T 6908) | Reflect the total amount of ion impurities in water to avoid corrosion of equipment |

| Hardness (calculated as CaCO₃) | ≤0.1 μmol/L | Complexation titration method (GB/T 6909) | Prevent scaling (CaCO₃, Mg(OH)₂ deposition) |

| Silicon dioxide (SiO₂) | ≤20 μg/L | Molybdenum blue spectrophotometric method (DL/T 502.2) | Prevent the accumulation of silicon scale on turbine blades, which may affect efficiency |

| Iron (Fe) | ≤10 μg/L | Phenanthroline spectrophotometric method | Prevent iron oxide deposition and avoid corrosion fatigue |

| Copper (Cu) | ≤3 μg/L | Atomic absorption spectrophotometry | Prevent copper ion catalyzed corrosion and protect precision components |

| PH value (25 ℃) | 6.5-8.5 | PH meter method (GB/T 6904) | Maintain water quality stability and reduce corrosion risks |

| Dissolved Oxygen (DO) | ≤5 μg/L | Sodium indigo disulfonate spectrophotometric method | Prevent aerobic corrosion (Fe → Fe²⁺+OH⁻) |

| Total Organic Carbon (TOC) | ≤200 μg/L | Combustion oxidation - non dispersive infrared method | Avoid the decomposition of organic matter to produce acidic substances |

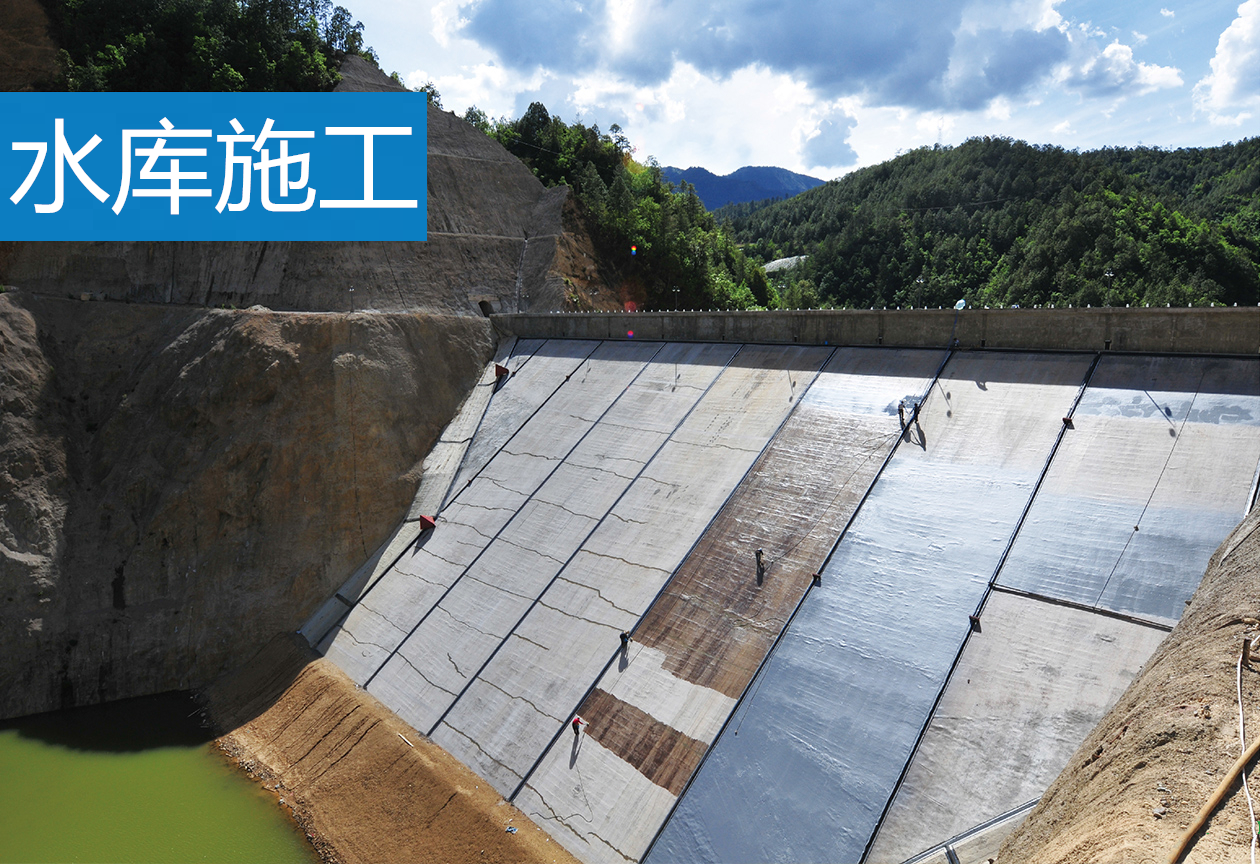

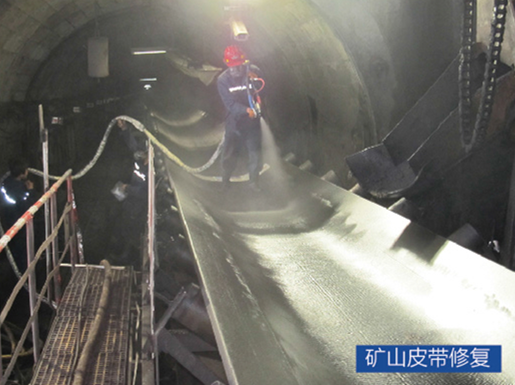

One of its components, the core function of the power plant desalination water tank, is to store and buffer "desalinated water" (used for boiler feedwater, turbine cooling, etc., with extremely high requirements for water purity, and no impurities or rust pollution allowed)

The anti-corrosion principle of nano explosion-proof materials: After curing, a seamless and high-density integrated protective layer is formed, completely isolating the corrosion of the carbon steel water tank substrate by desalinated water (high-purity, weakly corrosive), air, and trace impurities, avoiding substrate corrosion and pitting; At the same time, this material has extremely strong chemical stability, is resistant to water, weak acid and alkali, does not react with desalinated water, and does not release harmful substances, meeting the purity requirements of power plant water quality.